WWW.LOGISTICSINNOVATION.ORG

The online magazine for Switzerland, the EU and the rest of the world

RBG squadron at the Bosporus

October 31, 2025

TGW Logistics has announced an order for an automated small parts warehouse on the outskirts of Istanbul for Ekol Lojistik. The Turkish 3PL provider will use more than one hundred Mustang E+ stacker cranes on three levels to handle the storage and retrieval of retail and e-commerce orders.

"Omniverse" in the "Middle Kingdom"

October 31, 2025

As this year's CeMAT Asia Shanghai demonstrated, European technology remains a crucial factor for markets in the Far East. The Kion Group, with its AI and NVIDIA products, was once again in high demand at the three-day event, organized by Deutsche Messe (Hanover) in cooperation with partners .

Toni Gabriel is moving to TGW

October 30, 2025

“New job, new adventure!” says Toni Gabriel, who has just announced his new position as Sales Project Manager at the systems integrator TGW in Rotkreuz. He was impressed by the Austrian company TGW's combination of innovation, team spirit, and smart, future-oriented logistics solutions.

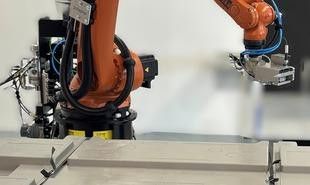

Pallets «unchained»

October 30, 2025

A system called "PolyCut" removes strapping from pallets, thus replacing time-consuming and ergonomically demanding manual work steps. It can be used as a stand-alone solution or integrated into existing handling systems and their controls or warehouse management systems.

High destructive potential

October 30, 2025

As feared, the US tariffs are causing a collapse in tech exports. According to Swissmem, the resulting negative effects took full effect within seven weeks in the third quarter. Exports from the Swiss tech industry to the US plummeted by 14.2% compared to the same quarter of the previous year .

Swiss Logistics Campus in Zofingen officially opened

October 29, 2025

Numerous visitors, friends and the entire crew of the new Swiss Logistics Campus of the Swiss Association for Vocational Training in Logistics, Swiss Logistics by SVBL ASFL, found their way to the official opening of the impressive new location in Zofingen over the weekend.

Leading in intralogistics with robots

October 29, 2025

the International Federation of Robotics' (IFR) annual report "World Robotics 2025 - Service Robots," approximately 102,900 robots for transport and logistics tasks were sold worldwide in 2024. Sales increased by 14 percent in 2024. More than three-quarters came from Asia, and 11 percent from Europe.

"Organic" combined with high tech

October 29, 2025

High-tech and products processed from natural ingredients are not mutually exclusive. "Organic" does n't mean everything is done manually, but rather that it adheres to high ecological standards. This is also true for the organic wholesaler Weiling, where an AutoStore system has recently enabled peak logistical performance.

Ready for the "Great Leap"

October 28, 2025

Founded in Xuzhou in 1943, the Xuzhou Construction Machinery Group (XCMG) generates approximately €13 billion in revenue with 13,000 employees worldwide. Its portfolio includes construction machinery, cranes, commercial vehicles, and a growing range of material handling equipment and port handling machinery.

Completely unmanned logistics?

October 28, 2025

Warehouse robotics specialist Geekplus is launching its new picking station "Geek+ Brain," ushering in a new era of warehouses operating entirely without human workers. CEO Yong Zheng " a major step from partial automation to full process intelligence . "

Hydrogen refueling at the Linde plant

WAGNER Switzerland AG

Hydrogen refueling at the Linde plant

May 11, 2023

Linde Material Handling is now producing green hydrogen for 21 fuel cell forklifts in Aschaffenburg. The plant, installed directly at the plant and supported by the German Ministry of Transport, went into operation on Thursday.

In addition to the targeted climate neutrality, the rapid refueling of industrial trucks with hydrogen during intensive multi-shift operations is a major advantage. "A three-minute refueling time corresponds to a comparable electric charging capacity of approximately 480 kW," said Prokosch, Head of Brand Management, at the opening.

"In our search for possible solutions, we see hydrogen as an option in the energy mix of the future." This applies not least to applications in intralogistics.

Furthermore, with the increased use of renewable energy sources in the future, the energy source could also function as an energy storage device, for example, to temporarily store electricity generated by photovoltaics or wind power. "We want to have the entire range of energy supply solutions in our portfolio. With this strategy, we remain open to different developments. Because nobody knows exactly where the journey will ultimately lead," explained the top brand manager.

Approximately €2.8 million was invested in the planning and construction of the hydrogen infrastructure. The production facility was built within eleven months on a 280 square meter existing site in a convenient location within the manufacturing and assembly plant. Around 50 subcontractors were involved in the construction of the hydrogen infrastructure under the direction of the general contractor Covalion, a Framatome brand, and the construction department of Linde MH.

Fig.: Linde MH

The plant components of the hydrogen infrastructure are distributed across several modules. At its heart is a PEM (polymer electrolyte membrane) electrolyzer, capable of producing 50 kg of hydrogen per day. Here, purified and deionized drinking water is separated into oxygen and hydrogen using green electricity. In another container, the hydrogen is gradually compressed to 450 bar and then fed via pipes and valves into the high-pressure storage tanks. A software-controlled valve system regulates the supply to the dispenser, the fuel pump. Employees connect the vehicles here with just a few simple steps. The high-pressure storage tank is designed to store up to 120 kg of hydrogen at 450 bar, allowing it to cover demand peaks caused by increased refueling at shift changes.

The 21 electric counterbalance forklifts with fuel cell hybrid systems currently in use at the plant, including twelve Linde E50s with a 5-tonne load capacity and nine Linde E35s with a 3.5-tonne load capacity, are replacing the previously used models with combustion engines. As part of the plant fleet, their tasks include loading and unloading trucks and supplying the assembly lines with large and heavy components such as counterweights, pre-assembled frames, and driver cabs. The vehicles emit no emissions during operation. The hydrogen and oxygen in the ambient air react in the industrial truck's fuel cell system. The generated electrical energy charges a lithium-ion battery that powers the forklift. The only "byproducts" are water and heat.

In addition to the Linde forklifts, other technical solutions from the company are also being used. For example, the explosion-proof access control of the Linde:connect fleet management solution ensures that only authorized and trained personnel can use the hydrogen plant. The explosion-proof "Safety Guard" safety assistance solution at the dispenser and in the vehicles automatically reduces the speed of the forklifts in the vicinity of the filling station. Last but not least, the "Linde Energy Manager" energy management solution enables intelligent planning and control of energy demand across the entire site, avoiding peak power demand and optimizing costs.

The first fully operational forklift prototype with a fuel cell drive was built back in 2000. Since 2010, fuel cell forklifts have been integrated into series production, and today, 80 percent of the series, including counterbalance forklifts, tractors, and high-lift trucks, can be ordered as a "customer-specific solution" with hydrogen drive.

In numerous studies and projects, Linde MH, together with partners from industry and science, demonstrated the conditions under which fuel cell forklifts are marketable and already cost-effective today. This is especially true when a hydrogen infrastructure is already in place on site or when high-purity hydrogen is generated as a waste product in operational processes. Fuel cell forklifts are also suitable for multi-shift operations with intensive use and high annual operating hours indoors, or when space for charging or battery-changing facilities is limited, which also needs to be saved.

Parallel to the construction of the hydrogen infrastructure in Aschaffenburg, the development and production of its own fuel cell systems is being advanced at Kion's parent company. At the LogiMAT trade fair, Linde MH presented its first proprietary 24-volt system for warehouse equipment, developed at the Aschaffenburg site.

The team is working on a rapid implementation of the development of a 48-volt fuel cell system. "By bringing the development of fuel cell systems and lithium-ion batteries in-house, we also have the opportunity to design our own, fully integrated fuel cell hybrid systems in the future, tailored precisely to the requirements of industrial trucks," says Prokosch.