WWW.LOGISTICSINNOVATION.ORG

The online magazine for Switzerland, the EU and the rest of the world

A brilliant start in Bern

November 6, 2025

The commercial vehicle trade fair transport.ch got off to a brilliant start in the Swiss capital after a successful opening event on the first day, which was attended by several hundred participants. A well-attended Mobility Forum showcased the current state of technological developments.

RBG squadron at the Bosporus

October 31, 2025

TGW Logistics has announced an order for an automated small parts warehouse on the outskirts of Istanbul for Ekol Lojistik. The Turkish 3PL provider will use more than one hundred Mustang E+ stacker cranes on three levels to handle the storage and retrieval of retail and e-commerce orders.

"Omniverse" in the "Middle Kingdom"

October 31, 2025

As this year's CeMAT Asia Shanghai demonstrated, European technology remains a crucial factor for markets in the Far East. The Kion Group, with its AI and NVIDIA products, was once again in high demand at the three-day event, organized by Deutsche Messe (Hanover) in cooperation with partners .

Toni Gabriel is moving to TGW

October 30, 2025

“New job, new adventure!” says Toni Gabriel, who has just announced his new position as Sales Project Manager at the systems integrator TGW in Rotkreuz. He was impressed by the Austrian company TGW's combination of innovation, team spirit, and smart, future-oriented logistics solutions.

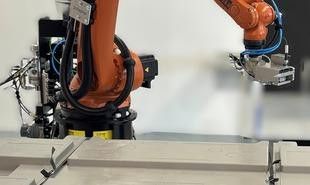

Pallets «unchained»

October 30, 2025

A system called "PolyCut" removes strapping from pallets, thus replacing time-consuming and ergonomically demanding manual work steps. It can be used as a stand-alone solution or integrated into existing handling systems and their controls or warehouse management systems.

High destructive potential

October 30, 2025

As feared, the US tariffs are causing a collapse in tech exports. According to Swissmem, the resulting negative effects took full effect within seven weeks in the third quarter. Exports from the Swiss tech industry to the US plummeted by 14.2% compared to the same quarter of the previous year .

Swiss Logistics Campus in Zofingen officially opened

October 29, 2025

Numerous visitors, friends and the entire crew of the new Swiss Logistics Campus of the Swiss Association for Vocational Training in Logistics, Swiss Logistics by SVBL ASFL, found their way to the official opening of the impressive new location in Zofingen over the weekend.

Leading in intralogistics with robots

October 29, 2025

the International Federation of Robotics' (IFR) annual report "World Robotics 2025 - Service Robots," approximately 102,900 robots for transport and logistics tasks were sold worldwide in 2024. Sales increased by 14 percent in 2024. More than three-quarters came from Asia, and 11 percent from Europe.

"Organic" combined with high tech

October 29, 2025

High-tech and products processed from natural ingredients are not mutually exclusive. "Organic" does n't mean everything is done manually, but rather that it adheres to high ecological standards. This is also true for the organic wholesaler Weiling, where an AutoStore system has recently enabled peak logistical performance.

Ready for the "Great Leap"

October 28, 2025

Founded in Xuzhou in 1943, the Xuzhou Construction Machinery Group (XCMG) generates approximately €13 billion in revenue with 13,000 employees worldwide. Its portfolio includes construction machinery, cranes, commercial vehicles, and a growing range of material handling equipment and port handling machinery.

The SUV in the all-wheel drive fleet

WAGNER Switzerland AG

The SUV in the all-wheel drive fleet

May 23, 2024

The hallmark of the new "L2 core" and "L2 lift" swarm transporters is their omnidirectional maneuverability thanks to their four independently steered and driven wheels. Safelog touts robust handling even over uneven surfaces and highlights the large loading area.

The basic L2 core model (without active load handling) is particularly suitable as a transport robot for goods-to-person processes or as an assembly platform. The Safelog L2 lift is equipped with a scissor-mounted lifting table. In addition to its further improved agility, the new mobile robot from Safelog offers an expanded speed range. For example, the maximum speed when running empty has been increased from 1 to 1.6 m/s compared to the previous L1 model. Also new is the crawl speed, in which the device moves at just 0.02 m/s. The crawl mode is useful, for example, in flexible assembly lines where the transport robot is used as an assembly platform.

For navigation, the robotics company offers virtual or magnetic guidance, depending on customer requirements. For spatial orientation, the robot can be equipped with the following localization methods to optimally adapt to the customer's specific application: LiDAR contour detection, grid code, ground structure detection, 2D camera system, RFID technology, inductive sensor, or magnetic sensor. Additionally, the L2 can be equipped with a 3D camera system for collision detection. The camera detects both people and objects. This further increases work safety and also prevents property damage.

Photos: Safelog

Photos: Safelog

Compared to the L1, the current model is 150 mm shorter and 30 mm lower. The compact design opens up new application possibilities, as the lower height allows for access to and lifting of more load carrier types. The new Safelog L2 lift model is equipped with a scissor-mounted lifting table that can accommodate and continuously raise up to 1500 kg. Compared to its predecessor, the L1, the maximum lifting height has been increased by 40 mm to 160 mm.

With a scalable battery capacity of LiFePO4 batteries, the batteries can also be charged wear-free via an inductive charging system.

Like all Safelog mobile robots, the new L2 model does not require a central control center for operation. Instead, the manufacturer pursues a swarm-based fleet management approach. Each robot is equipped with a processing unit running autonomous process software. This allows the devices, or agents, within the swarm to exchange the information they need to complete their respective tasks. If one robot fails, the others take over the tasks of the failed device.