WWW.LOGISTICSINNOVATION.ORG

The online magazine for Switzerland, the EU and the rest of the world

Flexible Automation in Bern

January 9, 2026

At Logistics & Automation on January 28th/29th in Bern, Dematic will present its flexible automation portfolio with solutions for new customers and for expanding existing systems, its autonomous mobile robots (AMR), AutoStore systems and pallet shuttles.

"Adjustments are unavoidable"

January 9, 2026

Zalando calls it "a difficult but necessary decision": the logistics center in Erfurt, Germany, is to be closed by the end of September. For more than ten years, 2,700 employees there made a significant contribution to the company's success. Now, restructuring is underway.

Fleet management in three stages

January 8, 2026

Forklift manufacturer Still, with its broad portfolio of in-house solutions for these situations, is calling on logistics companies at the start of the new year to operate their vehicle fleets efficiently and make the best possible use of potential savings. If necessary, this can of course be supported by AI.

Beumer expands production in China

January 8, 2026

The 90th anniversary of material flow solutions specialist Beumer and the 20th anniversary of its presence in China not only coincide. At the end of 2025, a new, state-of-the-art production facility also went into operation in Taicang, China, which is intended to expand Beumer's global production capacities.

A vibrant industry platform in every respect

January 7, 2026

On January 28th and 29th, "Logistics & Automation" will once again present future approaches to corporate logistics. Organizer Easyfairs discusses (part 3) with Peter Spycher, President of the Swiss Intralogistics Association, the leading Swiss platform for (intra)logistics, materials handling technology, and warehouse automation.

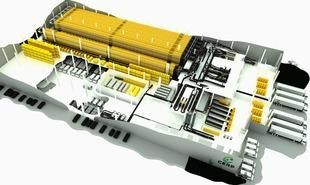

2900 product channels under control

January 7, 2026

SSI Schäfer is realizing a highly dynamic warehouse for the French pharmaceutical distributor CERP as a greenfield project with a high degree of automation, featuring a shuttle system and over 90,000 storage locations at its core, two piece picking robots, three pick stations and over 2900 product channels.

Bruno Jacques is the new head of healthcare

December 22, 2025

Bruno Jacques is the new CEO of Yusen Logistics Healthcare (Europe) and Vice Managing Director of Yusen Logistics Europe. He joined Yusen Logistics in 2018 as Managing Director of Yusen Logistics Benelux and Nordics, and at the beginning of 2024 his responsibilities were expanded to include Germany and Switzerland.

Sea freight with biofuel

December 22, 2025

The formula for biodiesel made from residual and waste materials is "Ucome" (Used Cooking Oil Methyl Ester) , which reputable suppliers claim offers CO₂ savings of over 90% compared to fossil diesel. DHL and CMA CGM now intend to accelerate the use of this biofuel.

With royal blessing

December 19, 2025

Not a battery-powered train the size of a model railway circling the Christmas tree, but seven real Mireo Plus B trains from Siemens: King Frederik of Denmark today inaugurated the trains that will replace the old diesel fleet in West Jutland and provide quiet, emission-free rail transport there.

Material Flow Congress integrated

December 19, 2025

The German Material Flow Congress will have a more live character in 2026, taking place as part of the Intralogistics Test Camp at the Westfalenhalle in Dortmund. During the conference, 25 speakers will discuss the trends of 2026 in technical logistics on April 15th and 16th.

Intralogistics as an economic factor

WAGNER Switzerland AG

Intralogistics as an economic factor

December 4, 2025

The «Logistics & Automation», Switzerland's leading trade fair for (intra)logistics, materials handling technology and warehouse automation, will open its doors again in Bern on January 28 and 29, 2026. Peter Spycher, President of the Swiss Intralogistics Association, discusses the future of an economic factor that has often been underestimated.

Mr. Spycher, the ILS now has 176 member companies, including 20 new members in 2025 – a new record. What role does intralogistics play today as a key factor for the competitiveness of the Swiss economy, especially in times of skilled labor shortages, increasing pressure for automation, and the growing use of AI applications?

Spycher : Intralogistics is becoming increasingly important for the competitiveness of the Swiss economy. Many companies have invested heavily in optimizing their supply chains in recent years, but have often barely questioned their internal material and information flows. This is precisely where enormous, untapped potential lies: even relatively small investments can achieve significant increases in productivity.

ILS President P. Spycher

ILS President P. Spycher

Considering that global robot production doubles annually, the profound changes expected in the coming years become clear. While the shortage of skilled workers long-term thinking in many companies. In ten years, our working world will look fundamentally different – and we will need to automate to a far greater extent not only in production and logistics, but also in the service sector .

The question of where all the necessary engineers and skilled workers will come from remains unresolved and represents a key societal problem. Artificial intelligence will support us in this transformation and enable new solutions that we can hardly imagine today. However, AI is not a panacea. Crucially, companies must begin today to holistically examine their processes and strategically work towards an automated future.

losing up to 500,000 workers by 2030. and automation, not only close this gap but also maintain the quality of "made in Switzerland"?

Switzerland is well-positioned in international comparison. Our strength lies in the close integration of mechanics, software, and robotics – a combination that is rarely found elsewhere. With institutions like ETH Zurich, we also have a high-performance technology cluster that significantly drives robot innovation in the industry .

Industries closely intertwined

The real challenge, however, lies not solely in the technology, but in the shortage of skilled workers. The number of young people entering technical professions is declining, and it is foreseeable that fewer will be entering these fields. At the same time, the demand for services is rising sharply. Sectors such as healthcare, entertainment, gastronomy, and hospitality will increasingly be in demand from an aging, financially secure population.

Logistics Talks at GS1

Logistics Talks at GS1

A look at Germany shows where things are headed: Around one million workers are currently leaving the labor market there each year – and simultaneously becoming a new source of demand for services, as many retire earlier and in better health. Another factor is growing prosperity: In Switzerland, over 100 billion francs were inherited this year for the first time to retire earlier

"Made in Switzerland" preserve

For intralogistics, this means that automation and innovative technologies are essential to closing the emerging labor gap and maintaining the high quality of "made in Switzerland." However, technological excellence alone is not enough. We must simultaneously ensure that sufficient skilled workers are trained to develop, implement, and operate these systems. Only the combination of technological innovation and targeted talent development will enable Switzerland to secure its competitiveness in the long term .

All photos: S.Barth / Easyfairs

All photos: S.Barth / Easyfairs

The second ILS study trip in October 2025 was fully booked with 50 participants and led to innovative companies such as Schindler, Swiss Post Cargo, and Meier Tobler. What were the key insights from this trip, and which innovation trends are currently the focus for the industry?

The second ILS study tour has definitively established itself as a key industry event and serves as a

true showcase of Swiss intralogistics. The companies visited presented themselves

with visible pride and provided an open insight into their state-of-the-art processes and solutions.

Exceptional added value

For companies facing automation decisions, the study trip offered exceptional added value: In just two days, different technologies, system architectures, and process approaches could be compared directly on-site. Many participants returned with concrete ideas for their own projects – from innovative material flow solutions to new software and robotics approaches (...).

The diversity repeatedly demonstrates that there is no single right solution, but rather many different paths to more efficient and resilient intralogistics processes. Several innovation trends shaping the industry became clearly visible: the increasing use of robotics and autonomous transport systems, software-driven process optimization, AI-supported planning and control, and flexible, scalable overall solutions. (...)

VR-supported shelf inspection

With its virtual reality (VR)-based training on rack inspection, ILS has launched a new approach to continuing education. How is this innovative training method being received by the industry, and what significance does systematic rack inspection according to SN EN 15635 have for operational safety in Swiss warehouses?

With VR-based training for rack inspection, a unique solution for increased operational safety has been created in Switzerland. A broadly based expert commission – consisting of users, manufacturers, the training organization, SUVA (Swiss National Accident Insurance Fund), and ILS Switzerland as a neutral professional association – jointly defined uniform standards for rack inspection according to SN EN 15635.

This collaboration ensures that the requirements are formulated in a practical manner and implemented uniformly throughout Switzerland. (...) Through the expert commission, which meets twice a year, new

findings and feedback from practical experience are continuously integrated into the training concepts.

(...) This ensures that the training remains current and up-to-date both technically and operationally. Several hundred specialists have already been successfully trained, and a comprehensive update of the VR solution is planned for next year, which will significantly improve the training even further.

Binding standards

The "ILS Shelf Specialist" quality seal is clearly recognized by the industry and is considered a binding standard. It guarantees that all examiners are trained according to the same criteria and are regularly invited to refresher courses – a crucial factor in maintaining consistently high quality and preventing a dilution of the standard.

Companies are well advised to specifically request specialists with this quality seal. Systematic rack inspections according to SN EN 15635 contribute significantly to operational safety and help to effectively reduce accidents, material damage, and downtime costs.

As a bronze medalist and prize partner for second place at the "SwissSkills 2025" vocational skills championships, ILS has made a strong statement in support of young talent. What insights do you take away from this event, and how can intralogistics become an even more attractive industry for young talent?

As an association, we have a responsibility to send clear signals and make visible the importance of promoting young talent, as our industry encompasses well over 60 different professions. The SwissSkills competition impressively demonstrates the commitment and passion with which young people work in logistics. Seeing this enthusiasm is motivating and confirms the immense potential of the next generation.

Demands are rising

With advancing digitalization and automation, jobs in the logistics sector are becoming more demanding and dynamic. This is precisely what makes them so exciting for young talent – provided we show them the career paths and make the diversity of this professional world tangible. Visibility is key: vocational competitions like SwissSkills, as well as trade fairs and practical training formats, contribute significantly to sparking interest and inspiring long-term talent for intralogistics.

Where does the industry need to do more to promote young talent? Are you planning anything special in this regard at the ILS booth at the "Logistics & Automation" trade fair in Bern?

The industry is already demonstrating strong unity: 20 companies are presenting themselves at the joint ILS booth, pursuing common interests despite some being direct competitors. This cooperation is a crucial element in promoting young talent, as it showcases the diversity, modernity, and future-oriented nature of intralogistics.

At the ILS booth in Bern, we are deliberately setting additional priorities. With the stand-up panel on the study trip, we offer a lively insight into the industry's innovative strength, and the communication corner with coffee will create a space for exchange between experts, young talents, and training companies. A key point is that we are also actively encouraging all members to clearly identify themselves as training companies. We will be sending out a flyer to all of them. Only when it becomes clear where young people can start their careers will we increase the long-term attractiveness of the industry and provide genuine guidance for the next generation.

The questions were asked by Markus Frutig on behalf of Easyfairs.

The full interview and further information will be available here

Free entry is available with the voucher code «1600» on the «Logistics & Automation 2026» website, which is also valid for the parallel «EMPACK» (www.empack-schweiz.ch).

Who is online

Currently, 2752 guests and no members are online.