WWW.LOGISTICSINNOVATION.ORG

The online magazine for Switzerland, the EU and the rest of the world

Flexible Automation in Bern

January 9, 2026

At Logistics & Automation on January 28th/29th in Bern, Dematic will present its flexible automation portfolio with solutions for new customers and for expanding existing systems, its autonomous mobile robots (AMR), AutoStore systems and pallet shuttles.

"Adjustments are unavoidable"

January 9, 2026

Zalando calls it "a difficult but necessary decision": the logistics center in Erfurt, Germany, is to be closed by the end of September. For more than ten years, 2,700 employees there made a significant contribution to the company's success. Now, restructuring is underway.

Fleet management in three stages

January 8, 2026

Forklift manufacturer Still, with its broad portfolio of in-house solutions for these situations, is calling on logistics companies at the start of the new year to operate their vehicle fleets efficiently and make the best possible use of potential savings. If necessary, this can of course be supported by AI.

Beumer expands production in China

January 8, 2026

The 90th anniversary of material flow solutions specialist Beumer and the 20th anniversary of its presence in China not only coincide. At the end of 2025, a new, state-of-the-art production facility also went into operation in Taicang, China, which is intended to expand Beumer's global production capacities.

A vibrant industry platform in every respect

January 7, 2026

On January 28th and 29th, "Logistics & Automation" will once again present future approaches to corporate logistics. Organizer Easyfairs discusses (part 3) with Peter Spycher, President of the Swiss Intralogistics Association, the leading Swiss platform for (intra)logistics, materials handling technology, and warehouse automation.

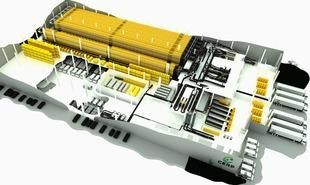

2900 product channels under control

January 7, 2026

SSI Schäfer is realizing a highly dynamic warehouse for the French pharmaceutical distributor CERP as a greenfield project with a high degree of automation, featuring a shuttle system and over 90,000 storage locations at its core, two piece picking robots, three pick stations and over 2900 product channels.

Bruno Jacques is the new head of healthcare

December 22, 2025

Bruno Jacques is the new CEO of Yusen Logistics Healthcare (Europe) and Vice Managing Director of Yusen Logistics Europe. He joined Yusen Logistics in 2018 as Managing Director of Yusen Logistics Benelux and Nordics, and at the beginning of 2024 his responsibilities were expanded to include Germany and Switzerland.

Sea freight with biofuel

December 22, 2025

The formula for biodiesel made from residual and waste materials is "Ucome" (Used Cooking Oil Methyl Ester) , which reputable suppliers claim offers CO₂ savings of over 90% compared to fossil diesel. DHL and CMA CGM now intend to accelerate the use of this biofuel.

With royal blessing

December 19, 2025

Not a battery-powered train the size of a model railway circling the Christmas tree, but seven real Mireo Plus B trains from Siemens: King Frederik of Denmark today inaugurated the trains that will replace the old diesel fleet in West Jutland and provide quiet, emission-free rail transport there.

Material Flow Congress integrated

December 19, 2025

The German Material Flow Congress will have a more live character in 2026, taking place as part of the Intralogistics Test Camp at the Westfalenhalle in Dortmund. During the conference, 25 speakers will discuss the trends of 2026 in technical logistics on April 15th and 16th.

Impressive study trip

WAGNER Switzerland AG

Impressive study trip

October 21, 2025

The Swiss Intralogistics Association (ILS) completed an insightful program with 50 participants, providing insights into state-of-the-art systems at the Container Logistics Center GLC, at Swiss Post Cargo in Villmergen, TGW on a BIM construction site, at Meier Tobler in Oberbuchsiten, Avosano and Schindler.

Accompanied by consistently positive feedback, this second ILS study trip was once again fully booked and, over two consecutive days, offered not only exclusive insights into modern logistics facilities but also a wide range of opportunities for professional and personal exchange. To kick things off, Aniko Hornyak from Transit Management led a tour of the "Port Innovation Lab" of elevator manufacturer Schindler, where the elevator provider's vision and work left a lasting impression.

Schindler City's Port Innovation Lab provided an opportunity to discover the future of mobility and learn exciting details about pioneering solutions for efficient transit management in buildings. 3D animations about the cities of tomorrow were watched with great interest.

Schindler, based in Ebikon and founded in 1874, is one of the leading providers of intelligent urban mobility ( Schindler PORT Innovation Lab | Schindler Group ) and is doing significant pioneering work for new technologies and innovations,

3D experience at Schindler

3D experience at Schindler

make urban spaces more comfortable, inclusive, and sustainable by transporting people and

Intelligent sorting technology in the GLC

The Container Logistics Center (GLC) in Villmergen represents intelligent sorting technology, ensuring significant efficiency gains and optimal planning in the food and retail industries. Half a million reusable containers are sorted, cleaned, and redelivered every day.

The Container Logistics Center in Villmergen.

The Container Logistics Center in Villmergen.

In addition, the blue CHEP pallets are inspected – a key hub in the supply chain of countless customers. GLC faced the challenge of optimizing its internal goods flows. With new container types and increased volumes, a more efficient, automated solution was needed to meet the increasing throughput requirements and current technology.

Up to date

Gilgen Logistics implemented a new, automated conveyor system (GLC Container Logistics Center) for the GLC. It spans several halls, connecting all processes into a single functional chain. Two buffer systems are the central element for regulating the flow of goods. Pallets and stackable containers are automatically recognized and sorted upon receipt. The entire conveyor system is highly automated, enabling smooth, optimal goods flow control.

The Swiss Post Cargo LHV. Photos (3): L. Lauffer

The Swiss Post Cargo LHV. Photos (3): L. Lauffer

A highly automated and multifunctional location has been in operation at the Swiss Post Cargo Logistics Center in Villmergen (LZV) since summer 2025. It offers comprehensive fulfillment solutions: from operational procurement and receiving to professional storage and picking, as well as transport and on-time delivery of customer goods.

Highly automated

The expansion into the largest warehouse logistics center of the Swiss Post will sustainably strengthen Villmergen as a business location. With 57,000 m² of space, the expanded warehouse in Villmergen offers space for everything that needs to be stored – from pallets and small parts to electrical appliances, hazardous materials, and pharmaceuticals. With state-of-the-art high-bay warehouses, digitalized Autostore systems, flexible space, and a dedicated team, the LHV ensures efficiency.

In addition to the installation of the automated high-bay warehouse with 23,000 pallet spaces, an automated mid-load warehouse with 20,000 trays, and the AutoStore small parts warehouse including material flow control for 125,000 containers, Swisslog was responsible for the MFC module of the SynQ software.

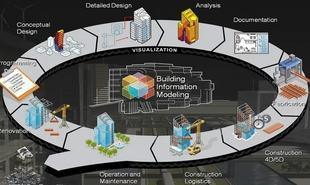

BIM-based realization

TGW visited one of Switzerland's most modern construction sites, where all production and assembly planning is implemented using BIM and a building information model. The construction project replaces an old production building that has reached the end of its service life after approximately three decades.

Building Information Model at Roche

Building Information Model at Roche

TGW Switzerland is implementing the state-of-the-art and innovative system, which will include four TGW Shuttle aisles with 21,200 storage spaces and three high-bay warehouse aisles with 6,300 storage spaces. In addition, the high-performance systems and the 12 picking workstations will be connected with container and pallet conveyor technology . A TGW material flow controller will control the entire flow of goods.

Fast delivery

Meier Tobler's Oberbuchsiten Service Center (DCO) replaced two former logistics locations in Nebikon and Däniken starting in mid-2023. The consolidation into a new, modern warehouse enables more efficient, flexible, and faster workflows, enabling customers to quickly and reliably supply ordered equipment, system components, assembly materials, and spare parts for heating, ventilation, air conditioning, and plumbing (HVAC) .

Meier Tobler in Oberbuchsiten.

Meier Tobler in Oberbuchsiten.

The massive building, with a floor area of almost 15,000 square meters, five floors, and a volume of 350,000 cubic meters, was constructed according to Minergie, the Swiss standard for low-energy buildings.

Gilgen Logistics implemented the future-proof intralogistics facility. The storage and picking processes are supported by an automated high-bay warehouse with 32,000 pallets, an AutoStore system with 43,000 containers and 35 robots for small parts, and pallet conveyor technology on several floors.

The warehouse management system with a material flow controller controls the logistics processes at a higher level. The high-bay warehouse is equipped with five latest-generation high-performance storage and retrieval machines. The lightweight design of the machines, coupled with a positive drive, allows for maximum throughput.

Custom-made

Avosano's industrial services enable customers to be delivered within two hours thanks to its state-of-the-art logistics centers and flexible delivery structure. As a pre-wholesale company, Avosano is highly specialized in pharmaceutical logistics services. In this capacity, it handles all warehouse logistics, processing, and distribution of pharmaceuticals on behalf of the pharmaceutical industry. Approximately 160 qualified employees ensure the supply of health and beauty products in Switzerland .

Avosano: Peak load is not a problem

Avosano: Peak load is not a problem

The Knapp Group implemented the expansion of Avosano. The Central Belt System (CBS) is a picking system that fully automates order processing, ensuring the required throughput times even during peak periods. The majority of order items are processed highly efficiently at the picking stations, which are automatically loaded by an OSR shuttle sorter system . In addition, fully picked orders are buffered in the OSR for transfer to the forwarding area at the exact time of loading.

In addition to the technical tours, the social program at the Sursee campus provided the ideal opportunity for informal discussions. A lively aperitif, the entertaining "Baggero" activity – which required technical skills and teamwork – and the festive banquet at the "Baulüüt" restaurant ensured a pleasant atmosphere.

Last year's event, which was organized by the ILS for the first time, took participants to renowned logistics locations such as Migros Aare Schönbühl, SBB Bahntechnik in Hägendorf, Swiss Post in Härkingen, Imbach Logistik in Emmen and Armasuisse in Thun.

The enthusiasm was palpable on this year's study trip, too – both for the logistics facilities visited and for the supporting program, says Lea Lauffer (Frei Fördertechnik), organizer and vice president of ILS Switzerland. "The feedback clearly shows that the study trip has established itself as a significant industry event in Swiss logistics."

Who is online

Currently, 2798 guests and no members are online.